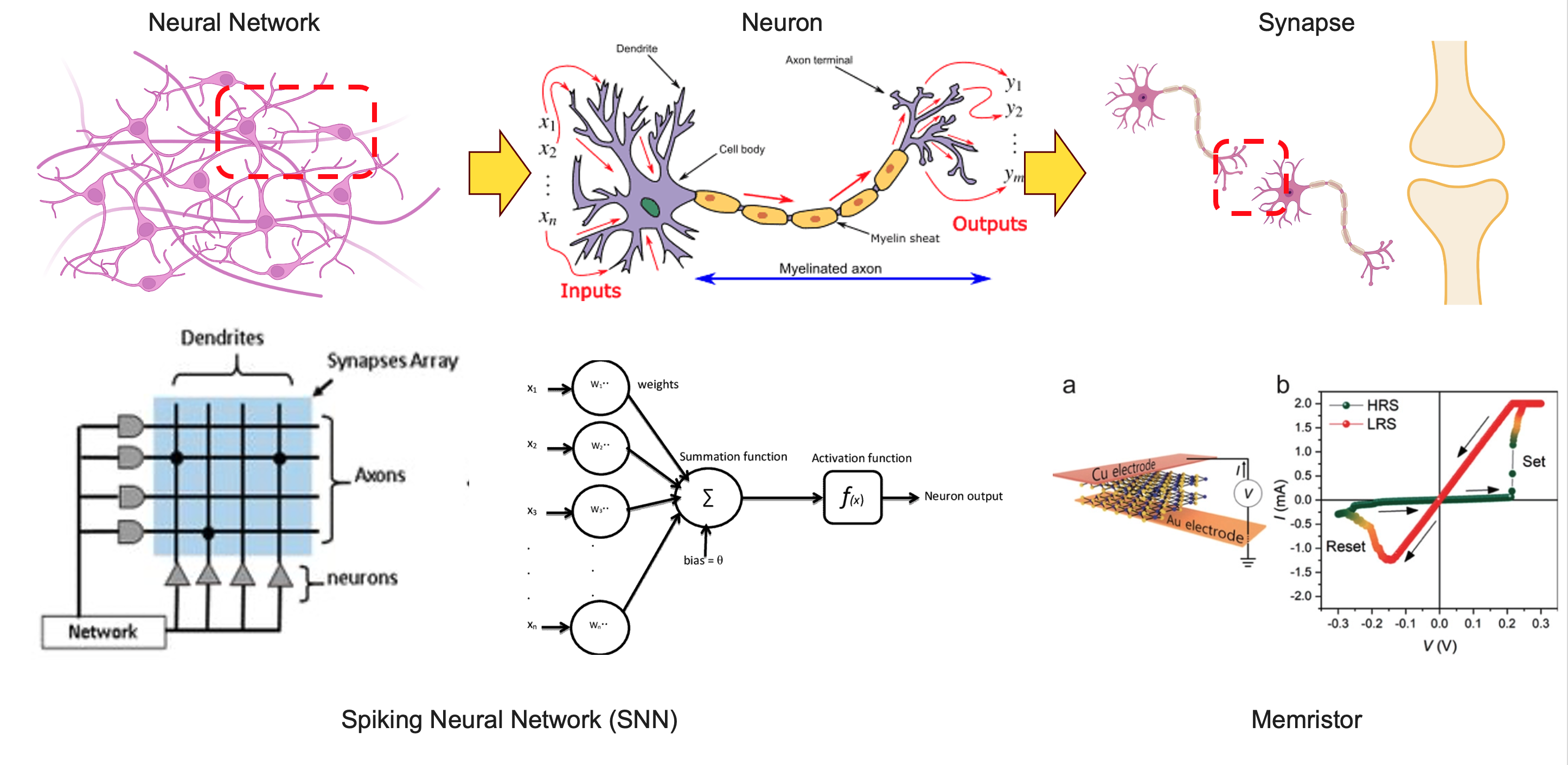

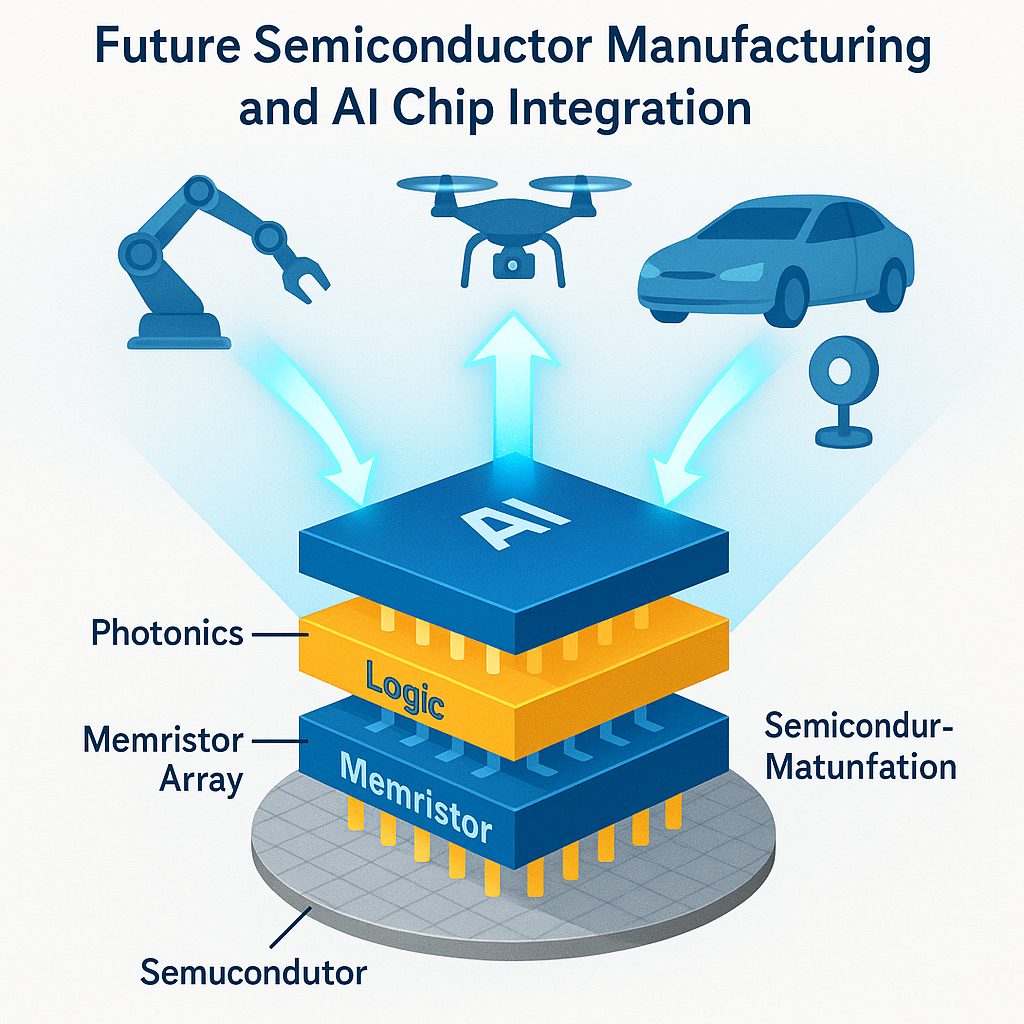

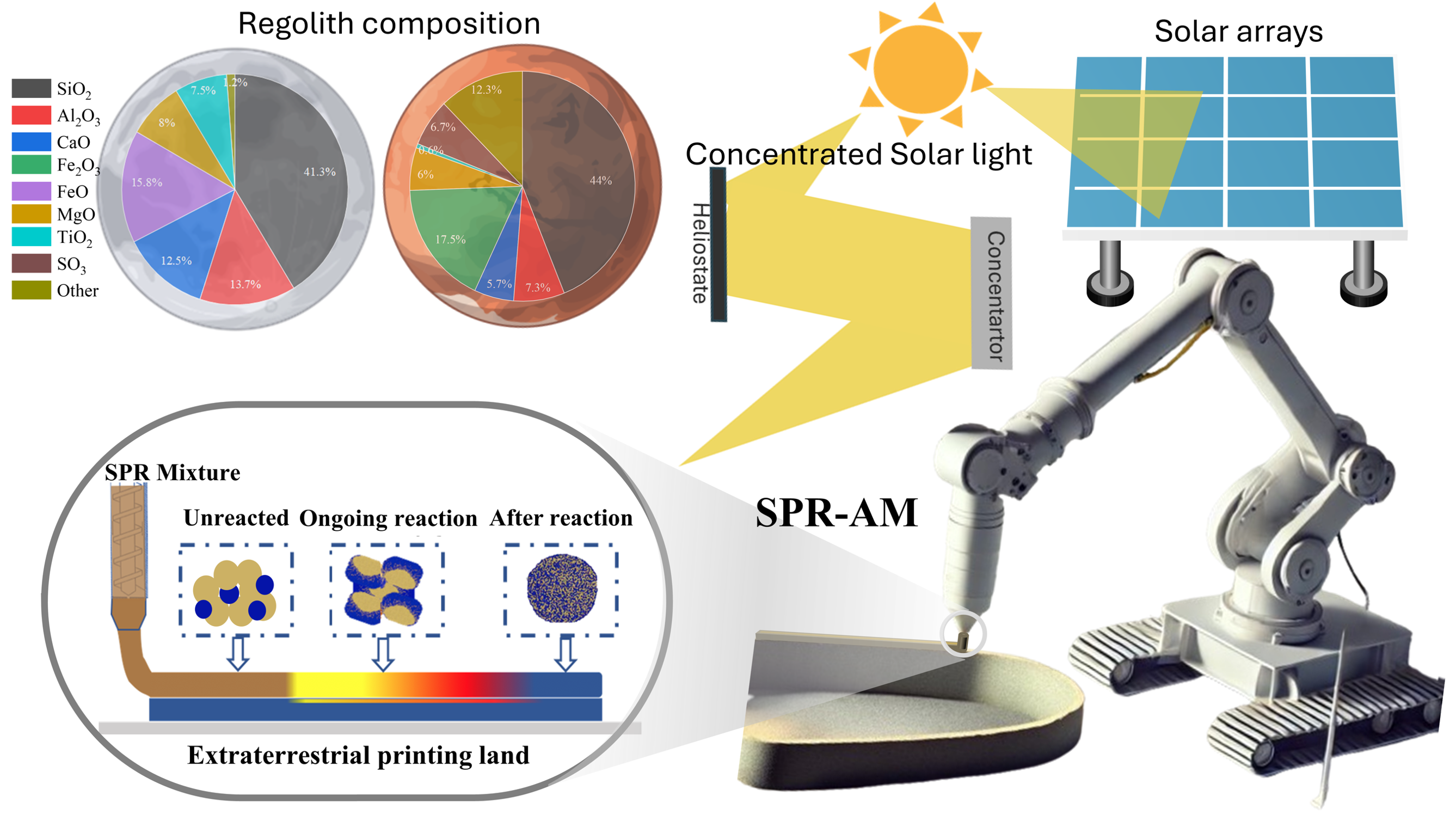

Modern manufacturing lacks energy-efficient, interoperable, and secure Edge AI systems capable of adapting to dynamic production conditions, limiting large-scale adoption. Emerging Edge AI, which delivers real-time, secure, and adaptive intelligence at the source, offers the potential to enable resilient, efficient, and autonomous production—driving a paradigm shift in manufacturing. Neuromorphic electronics have emerged as a breakthrough for Edge AI, enabling simultaneous data processing and storage with ultra-low power consumption. Our group aims to embed these capabilities into materials and manufacturing systems to create autonomous, intelligent production that senses, thinks, decides, and acts in real time.